Load Ka Expert Extra Strength for Extra Load Greyforce Paver Block

Manufacturing Process of Paver Blocks (Interlocking Bricks)

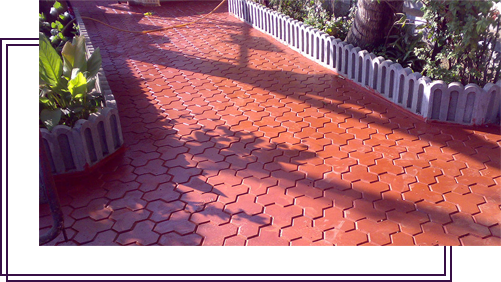

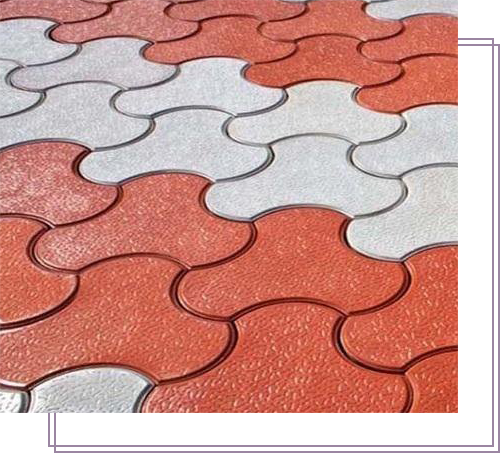

Paver blocks, also known as paving stones, are precast concrete blocks used for creating hard surfaces such as driveways, walkways, and patios. They are designed to interlock, providing a durable and aesthetically pleasing surface. They are manufactured at Raebareli plant using a specific process that involves several steps. The manufacturing capacity of plant is 2000 bricks per day.

Composition

- Cement: The primary binding material.

- Aggregate: Typically, crushed stone or gravel.

- Sand: For texture and strength.

- Water: Essential for mixing and curing.

Below is a detailed, step-by-step guide to the manufacturing process of interlocking bricks

Step 1: Raw Material Preparation

Soil Selection & Sieving: Choose soil with the correct clay and sand content, ideally 60% clay and 40% sand. Sieve the soil to remove large particles, stones, or debris.

Cement Addition: Add cement to the soil to enhance the strength and durability of the bricks. The soil-to-cement ratio varies based on the specific requirements and standards.

Step 2: Mixing

Mix the sieved soil with a stabilizer (cement or lime) and water in a specific ratio. Ensure thorough mixing to achieve a homogeneous mixture.

Step 3: Brick Molding

Place the mixed soil into the interlocking/Paver brick-making machine, which compresses it into the interlocking brick shape using a specific mold.

Step 4: Compression

Compress the soil-cement mixture using a hydraulic or manual press machine. This step ensures uniform density and strength throughout the bricks.

Step 5: Curing

Cure the newly molded bricks in a controlled environment for a specific period. Keep the bricks moist and covered for a few days to enhance strength and durability.

Step 6: De-molding

Carefully remove the cured interlocking bricks from the molds to avoid damage.

Step 7: Quality Control

Inspect the bricks for consistency in size, shape, and strength. Discard any defective bricks to ensure only high-quality bricks are used.

Step 8: Packaging and Storage

Stack and package the bricks in bundles. Store the packaged bricks in warehouses or outdoor storage areas, ready for distribution.

Applications

- Driveways and walkways

- Patios and courtyards

- Parking lots

- Public spaces and parks

- Landscaping features